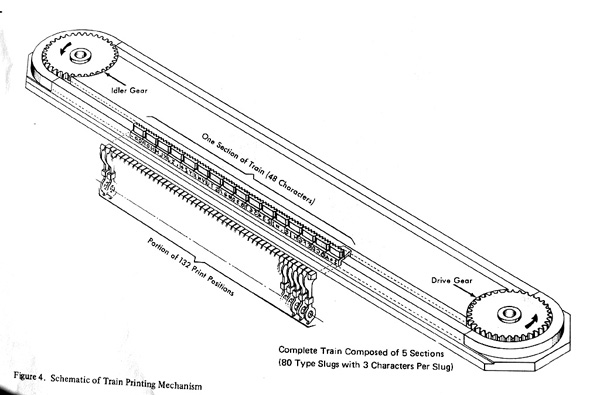

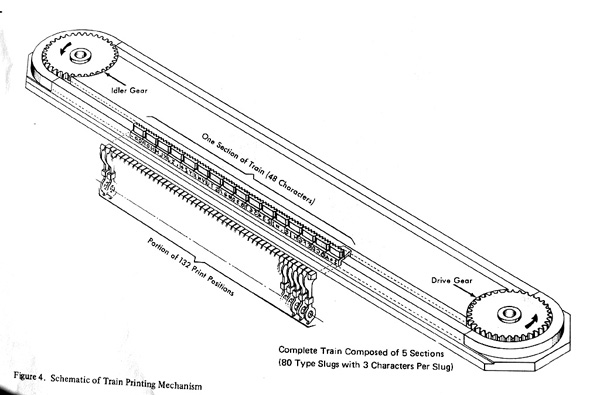

This is a diagram from a manual

IBM 1403 Printer Component Description.

In a high speed line printer the printing was done by

a hammer striking the paper on to an inked ribbon

behind which was passing a character on a horizontally

moving print chain/train/shuttle/band (see later).

The inked ribbon was the whole width of the bank of hammers

and moved vertically, as did the paper.

The chain/train/.. had five 48 character sections

so several hammers could be actuated at a time

making quite a bit of noise.

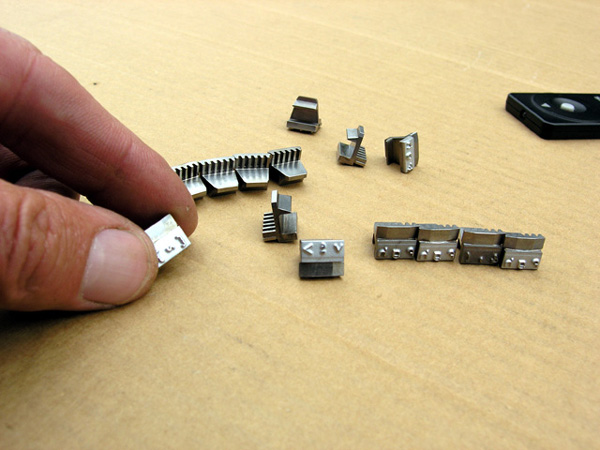

These are printer slugs for a printer train.

On the front of each were three characters,

and on the rear were flanges to restrain them in a track

and teeth to engage with drive wheels.

Printers using print trains were the fastest of printers

attaining 1100 Lines per Minute.

That could be 2420 hammer blows per second if

all 132 characters were printed per line.

For this reason the whole printer was encased in a cover

lined with sound absorbing material.

This was so effective that operators did not know the printer had stopped

because it had run out of paper.

So a nice feature was added,

the printer cover would open automatically

when it ran out of paper.