The bank of 3330-I disk drives was similar in size to the bank of 2314 disk drives.

But it was only half the weight (5074Kg), and used under half the electricity (20KVA),

and provided almost three times the storage capacity (800MB).

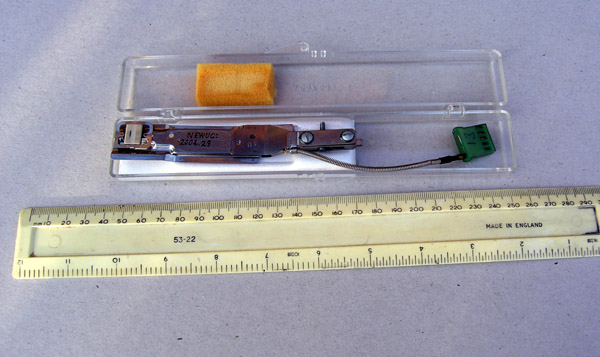

| Mus.Cat. NEWUC:2004.29 | Mnfctr: IBM | Date: 1974 | Part No: 2 345 271 A DOWN | Model: 3330-I |

| Comp: Disk read/write head | Length: 127 mm | Width: 21 mm | Depth: 16 mm | Weight: 19 g |

This is the read/write head assembly in its transportation container.

The improvement in capacity came about from a number of improvements:

This is a top view of the disk pack.

These disk packs were removable. A disk pack could be mounted on any disk drive.

This capability of changing disk packs allowed more disk storage than the number of disk drives,

but introduced a number of problems.

The movement of the disk pack from the drive to its storage place exposed it to dust, hair, fabric, etc.

As the head flying height was 50 microinch any particle on a disk surface could wedge between the read/write

head and the disk surface causing a head crash. Bad news, all data on disk lost.

This is the disk out of its container. You never handled a disk volume like this.

This is the bottom of the disk pack.

The most important aspect of the 3330 disk technology was the use of a servo disk surface

for positioning of the head assembly.

Hitherto the heads were positioned by an external mechanism to the disk, be it a stepping motor,

or a mechanical detent. The external positioning mechanism was subject to mechanical wear and tear,

and the head assembly position had to be constantly adjusted to compensate.

A servo disk surface was pre-recorded with a special data pattern for positioning the head assembly,

the servo surface read only head generated a signal that controlled the head assembly position

by altering a current in a voice coil in a strong magnetic field.

(It was called a voice coil because it operated in the same way as a coil in a loudspeaker,

but in the loudspeaker the coil is fixed to a diaphragm to generate sound, whereas in the disk drive

it moves the head assembly.)

Almost all subsequent disk drives used the servo mechanism to position the head assemby.

Later disk drives did not need to devote a whole disk surface to pre-recorded data

but used the data on the recording surfaces to position the head assembly.