| Mus.Cat. NEWUC:2015.32 | Mnfctr: Seagate | Date: 2011 | SERIAL No: 5QD4Y0MW | MODEL No: ST3750640NS |

| Comp: Disk Drive | LENGTH: 202mm | WIDTH: 107mm | HEIGHT: 25mm | Weight: 500g |

What is an Enterprise quality disk drive? It is not a desk-top computer disk drive.

| Enterprise | Desktop | |

| Duty | 24x 7 | some hours/day |

| Load | 100% | 20% |

| Performace | high | low |

| Reliability | multiple users High MTBF |

one user critical data backed up. |

| Data Integrity | High | Moderate |

There is a lot of information on the label on the lid. It is a Seagate Barracuda ES disk drive.

It gives the LOT, SERIAL and PART NUMBERs. It is marketed by Sum microcomputers

as a SATA 750GB 7200 RPM disk drive.

Removing the lid (8 screws) and prising the top magnet off, not easy to do, the two magnets on

either side of the copper voice coil are very strong.

The gap between the magnets and the voice coil is less than one millimeter.

Close-up of the voice coil.

There are five arms, one head on the top and bottom arms and two on the other three.

The top head is broken.

Bending it further up and closeup shows how complicated it is.

Seagate uses AcuTrac Technology on these drives. This means two actuators per head.

The voice coil moves the whole five arms to a position. Then, the read head senses the position of the

track and feeds back the error that causes the electronics to actuate dual piezoelectric nano actuators

near to the head, to keep the head closer to the centre of the track.

In this way the track density can be 340,000 tpi. (Tracks Per Inch)

The track width is 75 nanometers wide. That is 0.075 microns, a human hair is typically 100 microns.

The other is the bit density written on the track which is 926,000bpi (Bits Per Inch).

To get this density the disk is magnetised vertically. (Older disks magnetised horizontally.)

To put this another way, the track density is 13,386 tracks per millimeter and

the bit density is 36,457 bits per millimeter, making 488 million bits per square millimeter.

The underside of the drive.

The most prominent feature is the three copper conductors to the disk motor.

They carry three phase alternating currents that rigidly control the 7,200rpm (Revs Per

Minute)

rotation speed, which is critical for accurately writing and reading the bits.

The large 176 edge-connector chip (4x44) is a Seagate hard drive controller chip.

Pressing the square button on the right releases a handle which allows the disk to be unplugged.

This is the rear of the drive. At the lower middle is a 40pin (2 x 20pin) plug that connects to a socket.

This drive is "Hot swappable". Read on for an explanation of its use in a server cabinet.

|

This is the front of the cabinet. The disk drive was just one of many in a 19" rack, (the rack itself was wider than 19", the item inside was 19".) In this installation there are six rows of 16 disk drives, totalling 96 drives. If they were 750GByte drives that is 72TBytes. At the bottom of the cabinet is a Sun Microsystems server. |

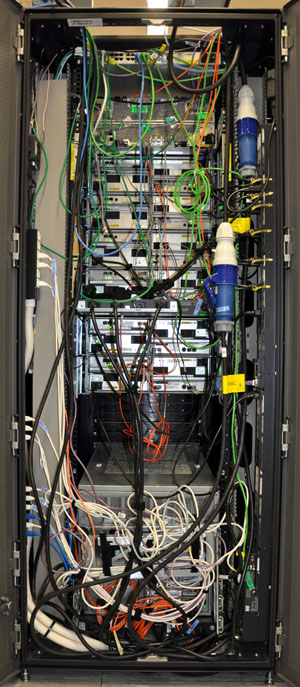

This is the rear of the cabinet. |

This type of installation is a worldwide server. It could be for email for thousands of people, or a web

server to millions, or a server for an online bank.

Whatever it is, it is crucial that it does not fail.

The whole installation will

be duplicated to a mirror installation by fibre optic connections to a

geographically remote location.

So every operation at one is replicated at the other in case one installation is destroyed.

Back to our disk drive. It was one of many in a RAID

Back to our disk drive. It was one of many in a RAID

(Reduntant Array of Inexpensive Disks.) installation.

The computer writes a block and a RAID controller splits

the block into N chunks, and writes the chunks to N disks.

Extra parity blocks are computed from the N chunks and written

across the drives such that, if a disk were to fail, the missing

chunk can be created from the (N-1) chunks plus the parity chunks.

This is done on the fly by the RAID controller.

If this is a permanent failure, a message is sent and someone

goes to the computer room, unplugs the failed drive, and inserts a new drive.

The RAID controller 'sees' this change and sets about reconstructing

the missing data.

Note the three indicators. On the right, labelled OK, is green.

The middle one has a 'hazard' symbol, on the left is a picture of

a disk being removed. It is important that when someone removes a

failed disk that they do not remove the wrong disk!

As disks become larger, the reconstruction time can become so long

that there is a possibility that there could be another error/failure

before the reconstruction is complete. So RAID has been enhanced to

to cope with a double disk failure by computing and writing two parity

chunks.

Back to DASD.